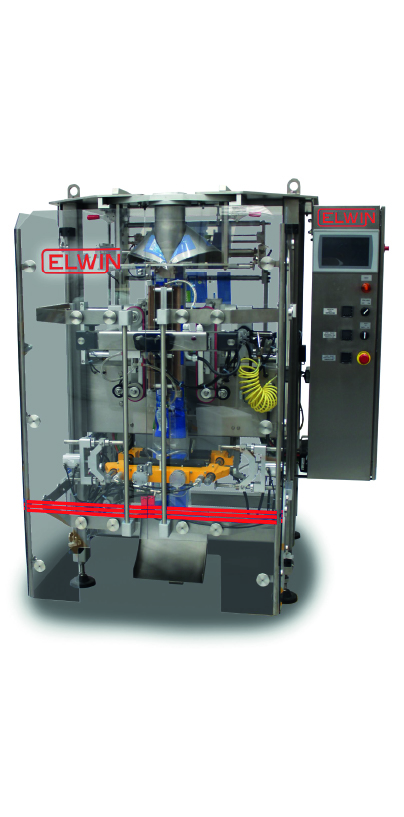

Máquina embolsadora vertical automática para formar, llenar y sellar bolsas de última generación, con estructura robusta de acero inoxidable con canales en “C” para una mejor higiene, con avance de película por medio de bandas de arrastre con servomotor y cierre de mordazas con servomotor.

Características:

Equipo complementario:

Dosificadores:

Tipos de bolsas compatibles:

Modelos y tamaño de bolsa:

| Dimensiones de Bolsa tipo Almohada (Ancho y Largo) | |||

| Mínima | Máxima | Velocidad Máxima | |

| BA280 | 63 X 60 mm | 280 x 406 mm | 70 BPM |

| BA355 | 80 x 100 mm | 355 x 508 mm | 60 BPM |

| BA430 | 100 x 100 mm | 430 x 609 mm | 50 BPM |