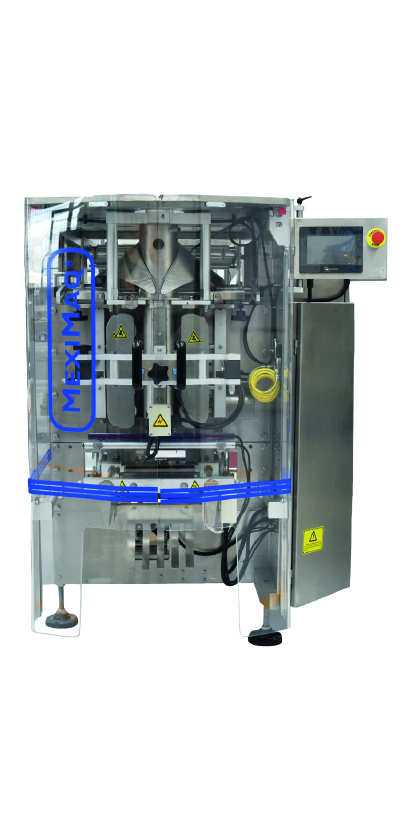

Máquina embolsadora vertical automática económica para formar, llenar y sellar bolsas, con estructura de acero inoxidable.

Características:

Equipo complementario:

Dosificadores:

Tipos de bolsas compatibles:

Modelos y tamaños de bolsa:

Dimensiones de Bolsa tipo Almohada (Ancho y Largo) | |||

| Mínima | Máxima | Velocidad Máxima |

CB200A | 60 X 60 mm | 200 x 300 mm | 50 BPM |

CB250A | 59 x 70 mm | 280 x 406 mm | 90 BPM |